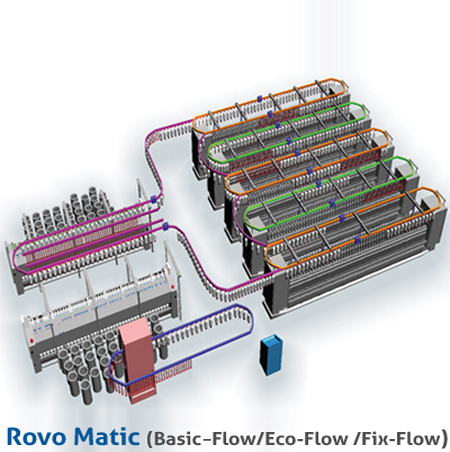

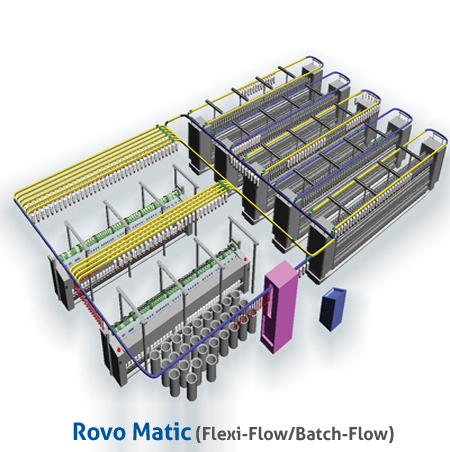

| BASIC FLOW | ECO-FLOW | FIX-FLOW | FLEXI-FLOW | BATCH-FLOW |

| End-less Loops of moving Bobbins on Alternate Ring Frames | End-less Loops of Moving Bobbins on Every Ring Frames | End-less Loops of Moving Bobbins Connecting a set of S/Fs & R/Fs with Tracks on Alternate R/Fs | Tracks on alternate R/Fs to have at- least one Track between every two R/Fs | Tracks on Every R/F to have at least one tracks on each side of A R/f and Connected By U Bends in the end |

| Each Loops Track is Extended By 1 Meter in Front of R/Fs For Creeling | Each Loops Track is Extended By 1 meter in Front of R/Fs For Creeling | Creeling is Carried at S/Fs and is very Convenient | Interconnected tracks to facilitate movement of Trains with full Flexibility | Interconnected tracks to facilitate movement of Trains with full Flexilbility |

| Speed of Each Endless Bobbin Train is Fixed and Uni Directional | Speed of Each Endless Bobbin Train is Fixed and Uni Directional | One Moving Track Between Every two R/Fs and One Extra Stationary Track For Every Moving Track On S/Fs | Tracks are extended & Interconnected to all S/Fs For Convenient Creeling and Movement of Material | Tracks are Extended & Interconnected to all S/Fs for Convenient Creeling and Movement of Material . |

| Each Endless Bobbin Train has a Control Panel for start/Stop/& auto Stop Functions | Each Endless Bobbin train has a Control Panel for start/Stop/& auto Stop Functions | Speed of each Loop can be Controlled for Speed Direction & Auto Stop with Individual control Panel | Sufficient Parking Storage area is also connected to all S/Fs & R/Fs providing Further Flexibility | Sufficient Parking Storage area is also connected to all S/Fs & R/Fs providing Further Flexibility |

| Bobbin Pitch of 220mm on Bobbin Trains | Bobbin Pitch of 220mm on Bobbin Trains | Bobbin Pitch of 200mm for Sufficient Storage | Master Panel with Software Controls the Material Movement based on the Requests Generated | Master Panel with Special Batch Creeling Software ensures easy Batch Creeling and Saves Man Power |

| Bobbin Trains Not Connected to S/Fs | Bobbin Trains Not Connected to S/Fs | Optional Loop for Rovo-Clean Auto Stripping M/C storage | Slave Panels for Registering Material Requests | Slave Panels for Registering Material Requests |

| Up-Gradable to Next Model Whenever Required at Nominal Cost | Up-Gradable to next model whenever Required at Nominal Cost | Auto Cleaning of Moving Castors by pneumatic Nozzles Provided for Each loop | Bobbin Train Automatically reach at entry point of R/Fs and from there the operator takes it Manually to Required Position within R/Fs | No Manual Movement of Trains as they automatically reach their destination at Selected batch section and goes into Batch Creeling Mode |

| Safety Features Such as Speed Sensors,Overload Sensors & Motors Temp Monitors are parts of The Standard Supply | Auto Cleaning of Moving castors by Pneumatic Nozzles Provided for Each loop | Safety Features Such as speed Sensors,Overload sensors & Motors Temp Monitors are parts of The Standard Supply | ||

| E | Automatic Rovo-Clean Bobbin stripping M/C is Optional with this system | Automatic Rovo-Clean Bobbin stripping M/C isPart of standard Supply |